Second life applications

1

Carboceramics Brakes

Petroceramics was engaged in the recycling of waste from prepreg production to fabricate brake discs for high-performance applications in automotive. Carbo-ceramics prototype-discs were realized adding prepreg scraps as a partial substitution of carbon fibre chops. Good results of physical, thermal and mechanical properties were obtained up to 10% of prepreg content. The material properties are comparable to reference state-of-the-art material without prepreg.

2

Automotive components

HP Composites proved that the reclaimed materials could be successful used to manufacture vehicle components. Two different components have been developed and produced by using recycled prepreg: an accelerator pedal frame and a bonnet. These two components prove the flexibility of the new raw material in manufacturing different kind of components (structural and aesthetical). A dedicated manufacturing process has been developed for an efficient and effective production. Outstanding results both in terms of performance and aesthetical quality products have been reached, saving 50 % of environmental impacts respect to state-of-the-art technologies.

3

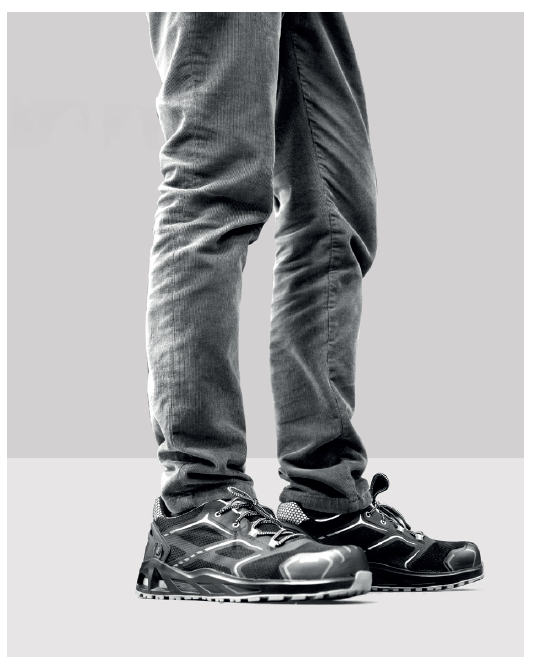

Toecaps

Using an experimental and numerical approach, CETMA and BASE PROTECTION worked strongly together to develop a new ecofriendly toecap, using carbon fiber prepreg scraps as raw material. The right thickness and layering of the composite material for the toecap for footwear was defined, with the purpose to reach high impact and compression resistances, as required in the Standard UNI EN ISO 20345. Structural optimization was conducted to improve the toecap design and performance and, also, to reach the best fit between the toecap and the commercial footwear line. The BASE PROTECTION KAPTIV line has been used for the testing validation. The results of laboratory tests have confirmed the good resistance of the toecaps made by 100% recycling material.